DESIGN BLOG

Builders - What to Anticipate in Home Construction in the Second Half of 2021

They say the only constant is change. And over the last year and a half, in the building industry, we’ve known this to be true. Some builders locked in prices for their clients, so that even as prices rise and fall, the price quoted to the client remains the same. Others have absorbed some costs, passed some costs on, or are somewhere in the middle. It’s important to remember we are all in this together–no matter how we are dealing with these unprecedented times

Image by Paul Brennan from Pixabay

They say the only constant is change. And over the last year and a half, in the building industry, we’ve known this to be true. Some builders locked in prices for their clients, so that even as prices rise and fall, the price quoted to the client remains the same. Others have absorbed some costs, passed some costs on, or are somewhere in the middle. It’s important to remember we are all in this together–no matter how we are dealing with these unprecedented times.

A few months ago, we wrote a blog, Construction Lumber - Demand, Pricing and Reducing Use. While costs for most products are still high, we are starting to see some changes. However, lumber demand and prices aren’t the only issues affecting builders here in central Ohio.

So, what are we to expect in the building industry for the rest of 2021?

Image by Paul Brennan from Pixabay

Shortage of workers

As home construction companies, we understand this all too well. We are all searching for skilled construction trade workers. Some of us are well staffed, but many of us are searching for qualified employees. And with that, the pool of available workers lowers and we all compete for the same people. The direct result of fewer employees–it takes us longer to get homes built, which affects our timelines and our ability to take on new projects.

Projects Are Moving Forward

This article from Cleveland Building & Construction shares the significant number of projects underway around Ohio. Columbus is leading the way with many massive projects occurring now. And the housing market continues to show no signs of slowing down. While we are still in a housing shortage, more homes were built last year than any year since 2006, says this article from The Columbus Dispatch.

According to this article from Columbus Underground, we do have the fastest selling housing market! With homes selling quickly, many people are planning on building new homes. How has this affected your build timelines?

Image by sawaeng wonglakorn from Pixabay

Lumber and Other Supplies

Lumber prices and supply has had a significant impact on builders here in Columbus. We are seeing positive changes as lumber prices are beginning to come down-slowly. Sawmills are beginning to increase production and people are returning to work (therefore not doing as many home renos and DIY projects). NAHB has been instrumental in working with the government to boost domestic lumber production, try to bring prices down and the get Canadian lumber supply lines back open, but it’s been an uphill battle so far. But as this article from NPR points out, it could take weeks or months for price reductions to take effect and prices probably won’t fall to pre-pandemic levels. But there is hope!

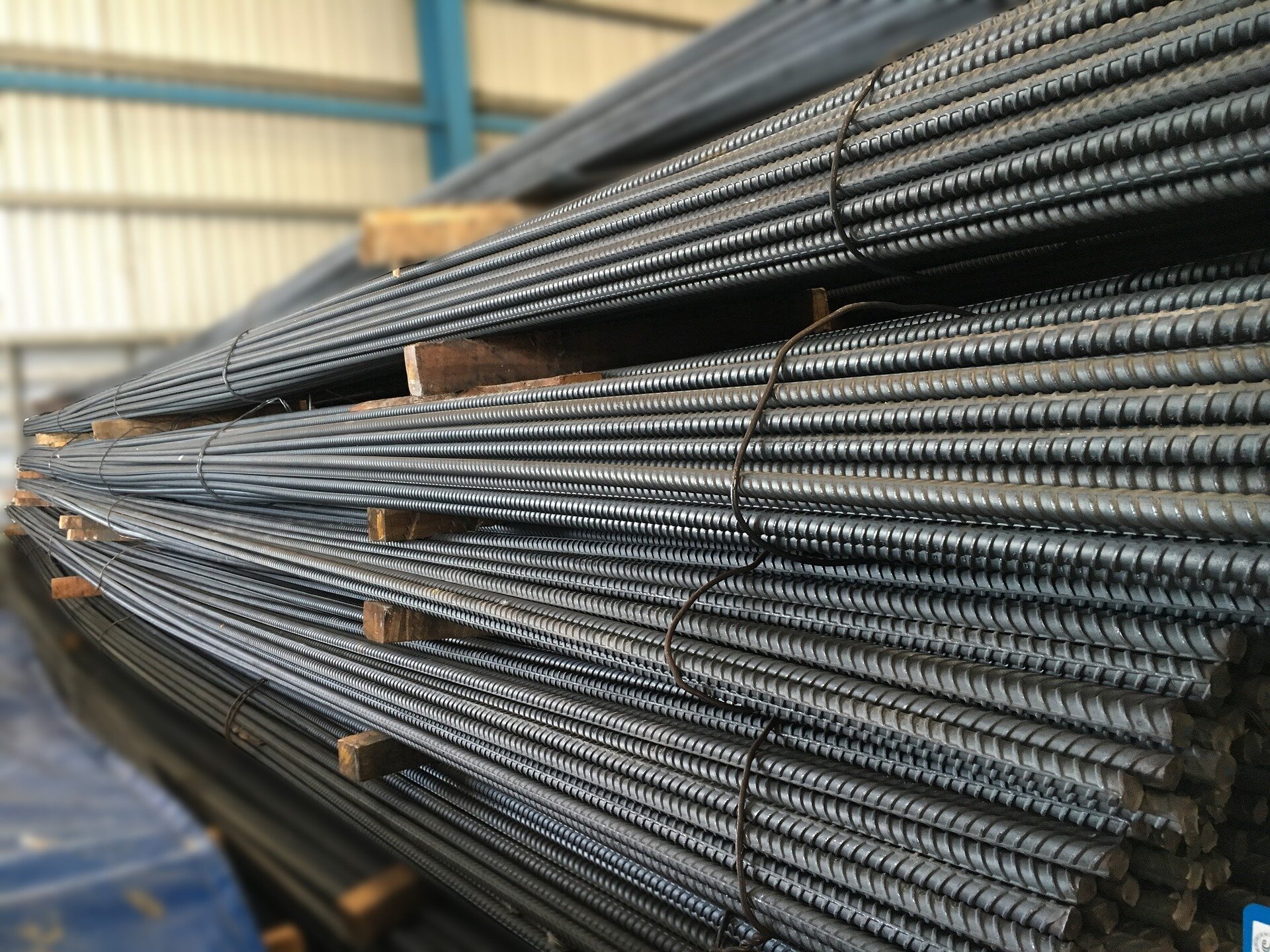

Iron, copper and steel tariffs are still expensive, and we know builders are trying to find ways to utilize less of it and find other ways to build homes using other products. This article from Construction Dive explains the ripple effect of these price increases. Steel for home construction (which includes studs, ductwork, beams, and some light fixtures), copper, vinyl siding, concrete, and gypsum, all continue to suffer from supply chain issues. This has continued to drive up the price, as well as the time to get supplies to the job site. Builders are looking at the use of insulating concrete forms, instead of wood framing. Structural insulated panels and steel frame construction are other framing methods utilized by some builders, hoping to keep costs down. But as we know, there are times when only iron and steel will do.

Supply changes are impacted worldwide, so many items are in short supply for home construction. You might get a home almost completed and then not be able to outfit it with kitchen appliances, windows, or other materials.

This article, from the U.S. Chamber of Commerce paints a rather dire picture (while giving us some hope), but we recognize we are luckier than most in Columbus. But if you have clients that do not understand what is happening, this might be worth having them read.

The challenge? Creating viable timelines, costs (what you pass on and what you absorb), waiting for prices to go down, finding skilled workers, and keeping your clients happy! What is working for you? What can we all learn from one another?

In Other News:

2019 BIA Parade of Homes, SIerra Custom Homes

BIA Parade of Homes

In case you haven’t heard, it is back! Are you participating or just going to see what others have been up to this year? There is still time for your home to be featured as an on-line Virtual entry. Click here!

At RDS, our designers are here and ready to help you create the home construction design your clients are asking for. Give us a call and let’s work together!

Construction Lumber: Demand, Pricing, and Reducing Use

Most homes can’t be built without lumber. And as designers, we create house plans utilizing wood. As we well know, lumber prices continue to rise. From mid-April to mid-September 2020, the cost of framing lumber grew by 170%. What is causing this increase and what effects are we feeling in the industry? Is there anything we can do as designers and builders to make better, more cost-effective decisions when using lumber in construction?

Most homes can’t be built without lumber. And as designers, we create house plans utilizing wood. As we well know, lumber prices continue to rise. From mid-April to mid-September 2020, the cost of framing lumber grew by 170% (link). What is causing this increase and what effects are we feeling in the industry? Is there anything we can do as designers and builders to make better, more cost-effective decisions when using lumber in construction?

Lumber Prices are High – Why?

Demand continues to grow even as supply continues to be difficult to get. There is world-wide construction growth, which impacts prices all over, especially here in the U.S.

The pandemic has had a direct correlation to soaring prices. More homes are being built, decks are being added, and businesses are pivoting to create more outdoor spaces and dining options.

Shutdowns, increased safety protocols slowing production, recent wildfires, and increased demands for timber in industries other than construction are all adding to the shortage and price increases.

Canadian lumber has not been exported as much as in recent years, due in part to the U.S. raising import duties.

The Effect on Housing Costs

Buyers are paying more for mortgage costs, but it appears they are ready and willing to do that.

With the high demand for new construction, builders continue to build for the foreseeable future. As the pandemic recedes, lumber prices should lower over time as they ramp up production again.

Some builders are having to back out of construction projects due to the rising cost of lumber.

The enhanced lumber costs will be passed on to the consumer when purchasing or building a new home.

Some builders are renegotiating contracts they have with buyers to account for the raised lumber costs and find savings in other aspects of the home.

The demand has shifted to the mid-range home market, meaning there is far less margin for error.

How to Reduce the Amount of Lumber You Use:

Thoughtful design can help control costs. Here at RDS, we are cognizant of the bottom line when designing your home. We know we can’t get away from using wood in most aspects of the build, but there are ways to reduce the amount of lumber purchased. With the cost of lumber at an all-time high, the following ideas may be worth consideration.

Build walls using advanced framing methods.

It’s cost-effective, structurally sound and uses resources more efficiently. Reducing the amount of lumber used and helping boost energy efficiency with more insulation is a framing technique that could help with the overall cost of materials and labor.

The changes involve walls with a 2x6 frame at 24-inch centers with single top plates, no jack studs, two stud corners, no cripples and single or no headers. Using less lumber and fewer pieces creates less expensive construction costs.

Since the framing is farther apart, the ease for plumbers and electricians to do their installations is also a benefit. Cavities are deeper, wider and fewer.

Advanced framing may be something you’ve dabbled with or use on every build, but we find utilizing this in our designs is appreciated by the builders for whom we create designs. For more detailed information, we suggest reading this Advanced Framing article from Mill Creek Lumber.

Image from https://www.apawood.org/advanced-framing

Image from https://www.apawood.org/advanced-framing

Utilize more metal framing or other alternative materials.

Check your lumber shipment before installing. An easy way to cut costs by double-checking that you received what you ordered.

Consider using engineered or manufactured wood to provide you with a more consistent lumber, which may lower labor costs.

Using our designers at RDS can be a great help. We will work with you to design homes with a more open floor plan and reduce the number of interior walls, reduce the number of corners on exterior walls, envision homes with creative uses of space-both vertical and lateral, or create gorgeous, yet simply designed homes with less complex framing.

All of our Certified Professional Building Designers at Residential Designed Solutions are adept at creating plans and visions to work with any budget you or your clients need. As a home designer, we know that while the design of the final home is the goal, final costs are just as important. We are here when you need a new home designer. Call us at 614.430.0027 to discuss your home construction build.